Markar HM304 Stainless Steel Hinge, Half Mortise

Markar HM304 is a Heavy-Duty Half Mortised Continuous Hinge which is mortised to the edge of the door and surface of the door frame with a cover channel to conceal fasteners on frame. This hinge is designed for door weighing up to 600 lbs. and a maximum width of 4'0". Hinge is Satin Stainless Steel and available in standard stock sizes, see below for details.

PRICED PER PIECE

Marker HM304 is a Pin and Barrel Type Continuous Stainless Steel Half Mortised Hinge.

-

Standard Sizes: 6'8", 7'0", 7'2", 8'0", 10'0". Custom sizing available, contact us or call at 845-388-1300 for details and pricing.

-

Applications: Supports weights up to 600 lbs. 4'0" maximum door width. Extra heavy duty for high traffic, high abuse door applications, including correctional facilities, high security locations and extra heavy doors. This hinge is used on wooden doors to hide splits, chips and dents from traffic abuse.

-

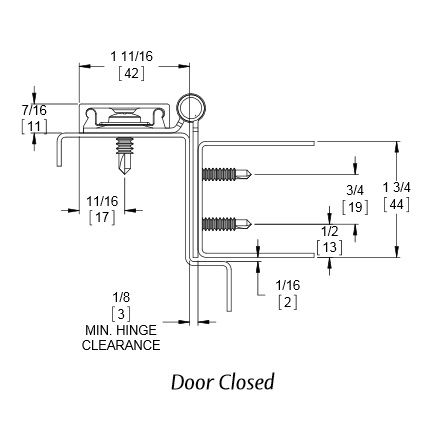

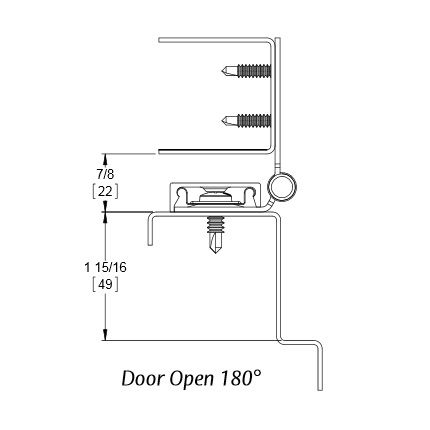

Design: Constructed from heavy-duty 14 gauge 304 stainless steel (US32D) .187" diameter 304 stainless steel pin (rod) with medical bearings and stainless steel end pins. Extruded aluminum cover channel to conceal fasteners on frame surface. Each knuckle 2", including split nylon bearing at each separation for a quiet, smooth, self-lubricating operation. Fasteners concealed when door is closed. Surface mounted frame leaf allows for easy retrofit installation.

-

Finish: US32D Satin Stainless Steel (630) on hinge, Brushed Aluminum on cover channel. Custom finishes are available, contact us or call at 845-388-1300 for details and pricing.

-

Mounting Hardware: Custom 12-24 x 11/16" S.S. Phillips Flat Head Undercut Tek Screws, 1/4-14 x 3/4" and Security TORX TEK Screws. Fasteners concealed when door is closed.

-

Handing: Specify Handing when ordering hinge. Select handing from options above. Not sure what handing is required for your door? See How to Determine Handing / Swing of Door.

-

Certifications: Fire-Rating: 3 hours on hollow metal doors. 90 minutes- hollow metal and composite. 20 minutes- wood door.

Classified in accordance with UL10C for positive pressure.

Evaluated in accordance with TAS 201-94, TAS 202-94, TAS 203-94, ASTM E330, ASTM E1886, ASTM E1996 and ANSI A250.13.

ANSI/BHMA Standard A156.26 Grade 1.

Note: Fire label for doors and frames should be placed on the header and top rail of fire rated doors and frames.

-

Modifications and Options: Adjustable monitoring switch, hospital tip hinges, medical bearings, dutch door hinge preparation, custom hole patterns, special sheared leaf, wide throw hinges, raised barrel(Swage), edge guard hardware cut-outs, special length hinges, Electrical Modification Access Prep, CTP-Current Transfer Preparation, CE - Current Transfer-Concealed, CT- Current Transfer- Contact Switch, ES-Exposed Monitoring Switch, Blank Hinges (Minus Hole Pattern), Lead Lined Cover (1/16" LEAD), Security Fasteners are available through our office. For details and pricing please contact us or call 845-388-1300.

-

Priced per Piece

- Please note, images are for illustrative purposes only. They are not actual photos. Therefore, actual colors may vary slightly and size may be enlarged to show detail. See product specs for exact measurements.

Click to view our Markar HG305 Hinge Guard Pin and Barrel Hinge.

This product has a 25 year warranty against defects in workmanship and material.

Click here to view our Full Warranty Policy.

Printable Documents: |

|

Click to print Markar HM304 Continuous Hinge Product Specs. |

Product Specs: |

|

Certifications: |

|

|

| Click to print Installation Instructions for Markar HM304 Pin and Barrel Hinge. |

General Instructions: |

|

All holes in the hinge must be drilled correctly and fasteners properly installed. Failure to use the fasteners supplied by our manufacturer will void the UL or WHI fire rated listing. Do not install Snap-On cover until installation is 100% complete and all aspects of the assembly are correctly fastened and properly fitted. The Universal Screw Pack contains sheet metal, machine and self-drilling Tek screws. This allows three different installation options. If mounting a wooden or unreinforced door, follow option A in the instructions. Follow option B if the door is reinforced or at least 1/8" thick. If you use the self-drilling Tek screws (recommended for grout-filled frames), follow option C. Perform each step of these instructions unless specifically labeled A, B or C. |

Installation: |

|

1. Place hinge on the edge of the door as shown in attachment. Carefully line up the hinge on the top and back edges of the door. 2. Mark all the hole locations on the door with the hinge held firmly in place. 3. Center punch each hole. The use of the Markar center punch can help center the hole that the fasteners will enter straight. The taper of the tool sits in the countersunk hole on the hinge. 4. A and B, drill all the holes using a #25 bit. 5. A. Attach the hinge to the door with #10 x 1 1/4" flat head undercut sheet metal screws. 6 B. Tap the holes for a 10-24 thread. Attach the hinge to the door with 10-24 x 3/4" flat head undercut machine screws. 7. Attach the hinge to the door with #10 x 1/2" flat head undercut self-drilling Tek screws. 8. Place the hinge and door in the opening. Place shims under the door to provide 1/8" clearance between the frame and top of the door. Add shims at both the hinge and latch side of the door so 1/8" clearance will be maintained on the lock side of the door. Swing the frame leaf of the hinge over the frame. 9. Molly Jacknuts are available through our office as an optional means of attaching the door. 10. C. Mark the position of the top and bottom holes with a center punch, then drill and fasten with self-drilling Tek screws. 11. Close the door and check for proper alignment. If the door requires adjustment for proper fit, make this adjustment by removing screws on the frame leaf and readjusting the door in the opening. 12. Permanently install the frame leaf with the remaining screws. 13. Install five cover clips by passing each screw through the clip, door leaf and door (see Fig. 2 on attachment.) It is recommended that clips be positioned in the top, center and bottom holes with the remaining two clips spaced equally along the length of the hinge. When installation is complete (See note at the top of these instructions), install the Snap-On cover. 14. Engage the side of the cover next to the hinge pin first. 15. Insert a large screwdriver between the hinge knuckle and the cover. Using the screwdriver as a lever, twist it and snap the opposite side of the cover onto the clip. 16. Start at the top and work downward until the entire length of the cover is firmly engaged. 17. With the cover firmly in place, secure it at both ends through the hinge and into the door with #8 x 3/4" self-drilling flat head Tek Screws. |